There seem to be an abundance of heat press options these days. From US made to Chinese brands, clamshell to swing-away, manual to automatic, and everything in between. So how do you choose a heat press that’s right for you? In this article we’ll consider some basic, although important, factors to consider before purchasing a heat press. Then hopefully you’ll be able to make an informed decision and get a heat press that’s right for you.

Heat Press BRAND

Why is the brand of a heat press important? The biggest reason is their reputation and reliability. Some brands are known for being ‘top class’ and producing high quality, long lasting machines that consistently deliver even heat. Some offer more economical but still decent quality presses. And other brands are known for having dirt cheap heat presses but with a 50/50 chance of it having cold spots or lasting no more than a month or two. So before purchasing the first heat press you lay eyes on, take time to research the brand or manufacturer and their reputation. Ask questions like:

- What do others say about this brand?

- Are they known for being reliable and standing behind their product?

- What kind of warranty or guarantee do they offer?

- Will they be readily available if I have problems?

Heat Press STYLE

In today’s garment decoration industry, there are basically 3 different styles of heat presses.

- Clamshell

- Swing

- Draw

Clamshell

This is, by far, the most common and popular style of heat press. This press opens by pivoting at the back of the machine, with the base remaining stationary and the top moving up and down.

Pros:

- Cheap. Because of the popularity of this style, pricing is very competitive. Some of the cheapest heat presses out there are the clamshell style.

- Compact. Because the top platen and handle only move up and down, you don’t need a lot of space behind or to the side of a clamshell style press.

- Simple. Because of the simple design of clamshell presses and few moving parts, there is less potential for things going wrong or breaking.

- Lighter Weight. Because of the simple design, the clamshell heat presses are generally lighter and easier to transport.

Cons:

- Not Accessible. Most clamshell presses don’t open to a full 90˚, but rather somewhere between 50˚-70˚. This means the lower platen where you place the garment isn’t easily accessible for placing and aligning transfers.

- Burnt Knuckles. Because of the limited space mentioned above, while laying out the garment or transfers, your hands will be under the hot upper platen. This means there is potential for burning your knuckles, especially when you’re in a hurry.

Swing

The Swing style press gets its name from the ability of the upper platen apparatus to swing to the side, while the base remains stationary.

Pros:

- Sturdier Construction. Because the heavy upper platen and arm mechanism has to easily swing back and forth, the overall construction of swing presses tend to be a little more heavy duty than the cheap clamshell press.

- Accessible Workspace. Since the top swings to the side, the entire lower platen is exposed for easy viewing, placement, and alignment of the garment and transfers.

- No Burnt Knuckles. With the hot upper platen swung to the side, you don’t have to worry about burning the tops of your hands.

Cons:

- Takes Up More Space. Because the top platen and arm swing to one side (sometimes almost a full 180˚) you need plenty of space to the sides and behind the press.

- Extra Step. After pressing and lifting the upper platen you have to take an extra few seconds to swing the top away. If you are always crunched for time, those few seconds could add up.

- Heavier and Bulky. Swing heat presses tend to be larger and heavier, thereby making them less than ideal for transporting to events, or being moved around the shop.

Draw

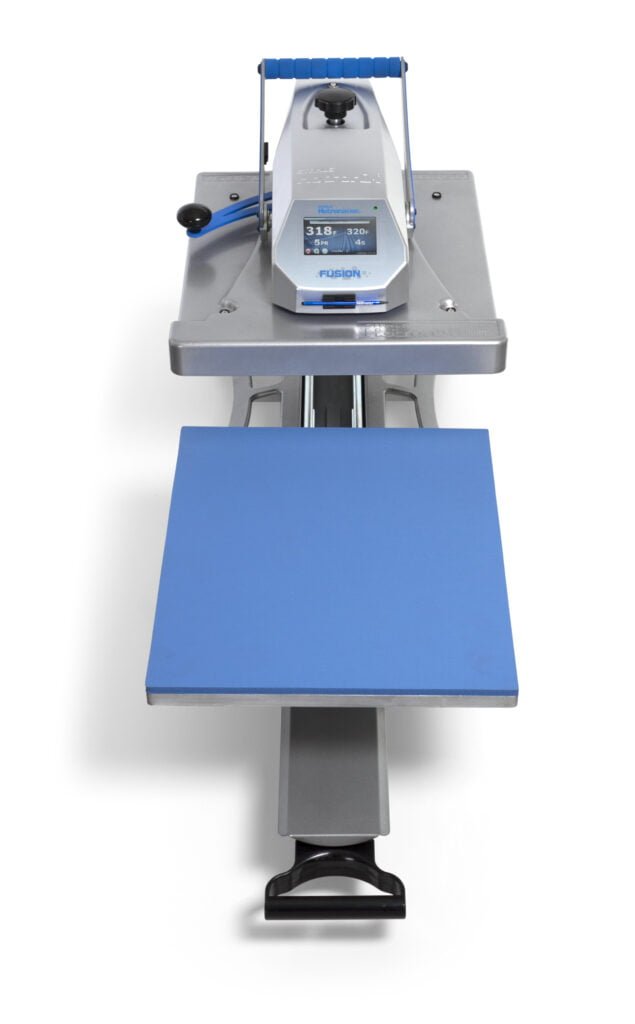

The Draw press (sometimes called a ‘Drawer’ press) gets its name from the lower platen’s ability to ‘draw’ out or pull out towards the user in the front.

Pros:

- Accessible Workspace. Since the entire lower platen pulls out from under the heated top platen, you get full access to the working area to place garments and designs.

- No Burnt Knuckles. Similar to the Swing press, the Draw press keeps your hands away from the heat while laying down the garment or transfer.

- Less Space Needed than Swing Press. Because the bottom platen draws out towards the front, not much (if any) extra space is needed.

Cons:

- Garment/Transfer Can Move. After placing the garment and transfer on the lower platen, pushing it back under the top platen could cause things to shift, resulting in a crooked design.

- More Moving Parts. Usually the lower platen slides on a ball-bearing rail. These bearings can wear down over time and through use (depending on the quality). Also, if exposed, this rail can cause your garments to get caught underneath, resulting in tears or grease stains.

Heat Press SIZE

There are a wide variety of sizes for heat presses these days, ranging from 5” up to 64”. But the most common sizes are: 9” x 12”, 11” x 15”, 15” x 15”, and 16” x 20”. What are the benefits of each of these?

9″ x 12″

This size is generally considered best for crafters, hobbyists, or even small startup businesses. It’s small enough to save on counter space, light enough to transport to craft shows, cheap enough to not break the bank but still delivers the same professional results as the larger sizes. (Find out more about the Hotronix Craft Press)

11″ x 15″

Like the 9” x 12”, this size is light and portable compared to larger presses. But the 15” width allows decorating larger designs on larger garments. There are also some more features available with some brands, like Auto-Open and Dual Digital Timer. If you’re looking to get a business started in garment decoration, this is a good size to begin with.

15” x 15”

This is an all around good size to decorate a variety of products. 15” x 15” is a large enough area to apply full front and back designs on t-shirts, youth jerseys, and other average size garments. And with many brands offering this size for $1000 or less, it’s a good investment for existing businesses looking to expand into heat transfers.

16” x 20”

If you want a press that gives you the ability to decorate, not only small items, but large jackets, adult jerseys, and other XL garments, then the 16” x 20” is the size for you. This size heat press is also available with the widest variety of features and options like: Auto-Open, Draw and Swing style, Touch Screen menu, Pneumatic (Air) operated, and more. If you want the flexibility to decorate most items and/or want some of the other productive features, the 16” x 20” size heat press is for you.

Heat Press FEATURES

As mentioned already, different sizes and styles come with different features. Some models are very basic while others come with productivity tech built in. So what are these features and why might you want them?

Digital Time and Temperature Display

While most heat presses come standard with this feature, there are still some that have an analog temp dial and twist knob timer/buzzer. With a ‘Digital Time and Temperature Display’, not only is it much easier and accurate for setting the temperature but also the timer will automatically start counting down after you engage the press and beep when it reaches zero.

Why might you want this feature?

Heat Transfers require a certain time and temp to apply properly. So making sure those 2 variables are accurate and easy to set will help you avoid mistakes which ultimately save you time and money. Though this feature might cost you a little more than a press with analog displays and controls, the price difference is minimal compared to the convenience you get.

Digital Pressure Display

Most heat presses don’t come with any way of measuring how much pressure you are using. Often it is left up to the user to determine this based on feel, though what may feel like a light/medium/heavy pressure to you may not be accurate. But having a ‘Digital Pressure Display’ allows you to see and accurately adjust the pressure.

Why might you want this feature?

One of the most common causes of heat transfer failures is incorrect pressure. But with a digital display telling you on a scale of 1-10 what your pressure is, you can be confident that the transfers are getting the right amount of pressure every time.

Touch-Screen Control Display

Standard controls on a heat press include physical buttons and a simple 3 digit LCD display. This only allows the user to see and adjust the Time and Temp. But a Touch-Screen Control Display allows users to see and adjust the Time, Temp, Pressure, as well as other advanced settings.

Why might you want this feature?

Not only does a Touch-Screen Controller allow you to easily see and change the basic settings (Time, Temp, and Pressure) but you can also save Preset Settings for different transfers, setup Auto On/Off times, keep a count of how many garments you’ve pressed, and more. These features can save you time, increase productivity and help reduce mistakes.

Pneumatic (Air)

A Pneumatic or Air powered heat press uses compressed air to close and open the press, and some models also use air to move the upper platen assembly back and forth. A dual button system is typically used to engage the press, keeping both hands out of danger from being crushed or burnt.

Why might you want this feature?

Air powered heat presses are great for large businesses and shops that are running their press all day long and producing hundreds to thousands of garments. With the compressed air doing the hard work, the user can focus their energy on loading garments and properly aligning the designs. Some smaller shops also invest in these machines since they last longer than manual heat presses and can be used by people of all different statures and strengths.

Interchangeable Platens

When the lower platen of your heat press is not the best size or shape for decorating a certain area or type of garment, an interchangeable platen can help a lot. These platens of varying sizes can be put in place of the lower stock platen, usually attached with bolts or a latch system.

Why might you want this feature?

Swapping out to smaller are different shaped platens can allow you to decorate small or odd shaped items like bags, kids clothing, pant legs, shoulders, etc… There are even specialty lower platens for things like shoes, gloves, can coolers, and hat bills. If you regularly deal with odd shaped items or have a demand for them, investing in an interchangeable platen could save you a lot of time and frustration.

Summary

Finding the right heat press for your business, budget, and situation can be challenging. But considering the Brand, Style, Size, and Features will help you to narrow down your search. If you’re wanting some suggestions on which press to get, here are some general recommendations from Wellington House:

- Beginners:

- Presses that are small and lightweight with fewer features will cost you less and are a good starting point for beginners.

- Intermediate:

- Larger heat presses with more than just the basic functions, although more expensive, allow you to decorate a wider variety of items and give you more convenient features.

- Professional:

- Large presses with time saving features and made for heavy use are best for pros that use their heat press every day to produce hundreds of garments.

Here at Wellington House, we always encourage our customers to do their research and ask questions before buying, especially for a larger investment like this. No matter what your budget or business needs are, our experienced team can answer your questions and help you decide on a heat press that’s right for you.

Get more details on the variety of heat presses at our website:

WellingtonHouse.com/HeatPress

Or you can talk to our team via phone or email.

What do you think of the suggestions offered? What are some ways you already manage your customer’s wait time? We would love to hear from you in the comments below.